Manufacturing Engineering: Enhancing Production Efficiency

Manufacturing engineering stands at the forefront of modern industry, blending traditional craftsmanship with cutting-edge technology to optimize production processes. From the early days of manual labor to the era of automation and digitalization, this field has continuously evolved to meet the demands of an ever-changing global market.

I. Introduction to Manufacturing Engineering

Manufacturing engineering encompasses a range of disciplines focused on the design, development, and improvement of manufacturing processes and systems. It plays a pivotal role in ensuring the efficient production of goods across various industries, including automotive, aerospace, electronics, and more.

II. History of Manufacturing Engineering

The roots of manufacturing engineering trace back to ancient civilizations where rudimentary techniques were employed to craft tools and goods. With the advent of the Industrial Revolution, mass production became feasible, leading to the formalization of manufacturing engineering principles.

III. Key Concepts in Manufacturing Engineering

Processes and Methodologies

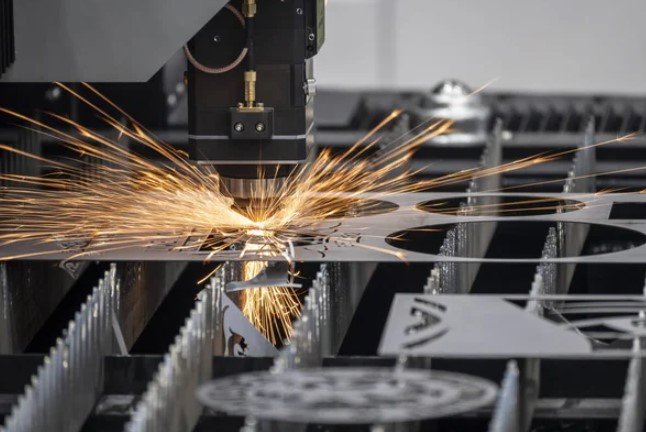

Manufacturing engineers employ a variety of processes such as casting, machining, welding, and 3D printing to transform raw materials into finished products. These processes are continuously refined to enhance efficiency and quality.

Lean Manufacturing Principles

Central to modern manufacturing engineering is the concept of lean manufacturing, which emphasizes minimizing waste and maximizing value. By streamlining processes and eliminating inefficiencies, companies can achieve higher productivity and profitability.

Automation and Robotics

The integration of automation and robotics has revolutionized the manufacturing landscape, allowing for greater precision, speed, and scalability. Manufacturing engineers are at the forefront of implementing these technologies to optimize production lines.

IV. Role of Manufacturing Engineers

Manufacturing engineers play a crucial role in the design, optimization, and maintenance of manufacturing processes and systems. They are responsible for ensuring that products are produced efficiently, cost-effectively, and with the highest quality standards.

V. Technologies in Manufacturing Engineering

Advanced Manufacturing Techniques

From additive manufacturing to computer numerical control (CNC) machining, manufacturing engineers leverage a variety of advanced techniques to achieve greater precision and flexibility in production.

Industry 4.0 and Digitalization

The fourth industrial revolution, often referred to as Industry 4.0, has ushered in an era of digitalization and connectivity. Manufacturing engineers harness technologies such as IoT, AI, and big data analytics to create smart factories and optimize supply chains.

VI. Applications of Manufacturing Engineering

Automotive Industry

In the automotive sector, manufacturing engineering plays a critical role in ensuring the efficiency and quality of vehicle production. From stamping and welding to assembly and painting, every aspect of the manufacturing process is carefully orchestrated by skilled engineers.

Aerospace Industry

In aerospace manufacturing, precision and reliability are paramount. Manufacturing engineers work closely with design teams to develop innovative production methods for aircraft components, engines, and avionics systems.

Electronics Industry

The rapid pace of technological advancement in the electronics industry requires manufacturing engineers to constantly innovate and adapt. From microelectronics to consumer gadgets, efficient production processes are essential for meeting consumer demand.

VII. Challenges and Trends

Sustainability Concerns

As environmental awareness grows, manufacturers are under increasing pressure to adopt sustainable practices. Manufacturing engineers are tasked with finding eco-friendly solutions that minimize waste, energy consumption, and emissions.

Emerging Technologies

From 3D printing of biodegradable materials to renewable energy-powered factories, manufacturing engineering is at the forefront of technological innovation. As new technologies emerge, engineers must stay abreast of developments to remain competitive.

VIII. Education and Career Paths

Aspiring manufacturing engineers can pursue undergraduate and graduate degrees in engineering disciplines such as mechanical, industrial, or manufacturing engineering. Additionally, certifications and professional development courses can enhance career prospects in this field.

IX. Conclusion

Manufacturing engineering plays a vital role in shaping the future of industry by optimizing production processes, embracing technological innovation, and addressing sustainability challenges. As global demand for goods continues to rise, the expertise of manufacturing engineers will be essential for driving efficiency and competitiveness.

X. FAQs

- What is the difference between manufacturing engineering and industrial engineering? Manufacturing engineering focuses specifically on the production processes and systems used to manufacture goods, whereas industrial engineering encompasses a broader range of activities, including optimization of entire systems and processes within various industries.

- How does manufacturing engineering contribute to sustainability? Manufacturing engineers play a key role in implementing sustainable practices such as waste reduction, energy efficiency, and recycling in production processes, thereby minimizing environmental impact.

- What are the prospects for career growth in manufacturing engineering? With advancements in technology and increasing demand for efficient production methods, the prospects for career growth in manufacturing engineering are promising. Skilled professionals can explore opportunities in diverse industries and roles, from production management to research and development.

- How can companies benefit from implementing lean manufacturing principles? By adopting lean manufacturing principles, companies can streamline production processes, reduce waste, improve quality, and enhance overall efficiency. This leads to cost savings, increased productivity, and greater customer satisfaction.

-

What are some examples of cutting-edge technologies used in manufacturing engineering? Examples include additive manufacturing (3D printing), advanced robotics, artificial intelligence, augmented reality, and digital twin technology, all of which are revolutionizing the manufacturing landscape by enabling greater customization, efficiency, and flexibility.