Industrial Engineering: Enhancing Efficiency and Productivity

Industrial engineering is a field of engineering that focuses on optimizing complex processes, systems, and organizations to improve efficiency, productivity, and quality. It encompasses various disciplines such as mathematics, physics, and social sciences to analyze and design systems that integrate people, equipment, materials, information, and energy. This article delves into the diverse facets of industrial engineering, from its historical roots to its modern-day applications and future prospects.

Historical Background

The roots of industrial engineering can be traced back to the Industrial Revolution of the 18th and 19th centuries when the focus shifted from artisanal production to mechanized manufacturing. Pioneers like Frederick Taylor and Henry Ford laid the groundwork for modern industrial engineering by introducing principles of scientific management and assembly line production.

Key Concepts in Industrial Engineering

Efficiency and Productivity

Efficiency refers to the ratio of output to input in a system, emphasizing the optimal utilization of resources. Productivity, on the other hand, measures the output generated per unit of input over a specific period, highlighting the effectiveness of a process or operation.

Optimization

Optimization involves finding the best possible solution to a problem within given constraints. Industrial engineers use mathematical modeling and algorithms to optimize processes, minimize costs, and maximize output.

Process Improvement

Continuous process improvement is a core tenet of industrial engineering, focusing on identifying inefficiencies, bottlenecks, and waste in processes and implementing strategies to streamline operations and enhance overall performance.

Scope and Applications of Industrial Engineering

Industrial engineering finds applications across diverse industries, including:

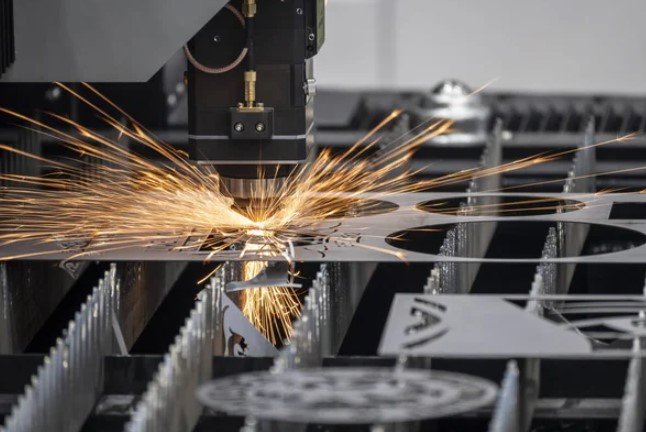

Manufacturing Sector

In manufacturing, industrial engineers play a vital role in optimizing production processes, reducing cycle times, and enhancing quality through techniques such as lean manufacturing and just-in-time inventory management.

Healthcare Industry

In healthcare, industrial engineers apply principles of operations research and system analysis to improve patient flow, optimize hospital layout, and enhance resource allocation, ultimately leading to better patient outcomes and cost savings.

Service Sector

In the service sector, industrial engineers focus on improving efficiency and customer satisfaction in areas such as transportation, logistics, and supply chain management through the application of optimization techniques and process redesign.

Tools and Techniques Used in Industrial Engineering

Lean Manufacturing

Lean manufacturing aims to minimize waste and maximize value by eliminating non-value-added activities, reducing inventory levels, and optimizing production flow to achieve greater efficiency and responsiveness to customer demands.

Six Sigma

Six Sigma is a data-driven approach to process improvement that aims to reduce variation and defects in manufacturing and service processes, leading to improved quality, cost savings, and customer satisfaction.

Operations Research

Operations research involves the application of mathematical modeling, optimization algorithms, and simulation techniques to analyze complex systems and make data-driven decisions to improve efficiency and effectiveness.

Importance of Industrial Engineering in Today’s World

Industrial engineering plays a crucial role in addressing contemporary challenges such as global competition, sustainability, and technological innovation by providing solutions to enhance productivity, reduce waste, and optimize resource utilization.

Career Opportunities in Industrial Engineering

Industrial engineering offers diverse career opportunities in fields such as manufacturing, healthcare, logistics, consulting, and academia, with roles ranging from process engineer and operations manager to supply chain analyst and quality assurance specialist.

Challenges and Future Trends in Industrial Engineering

Despite its significance, industrial engineering faces challenges such as resistance to change, integration of emerging technologies, and the need for interdisciplinary collaboration. However, with advancements in areas such as artificial intelligence, robotics, and data analytics, the future of industrial engineering looks promising, with opportunities for innovation and growth.

Conclusion

Industrial engineering plays a pivotal role in enhancing efficiency, productivity, and quality across various industries. By employing principles of optimization, process improvement, and system analysis, industrial engineers drive innovation and competitiveness in the global marketplace. As we navigate the complexities of the modern world, the importance of industrial engineering in shaping a more efficient and sustainable future cannot be overstated.

FAQs

1. What educational background is required to pursue a career in industrial engineering?

Industrial engineers typically hold a bachelor’s degree in industrial engineering or a related field such as mechanical engineering, with coursework in areas such as mathematics, statistics, and operations research.

2. How does industrial engineering differ from other engineering disciplines?

While other engineering disciplines may focus on specific technologies or systems, industrial engineering takes a holistic approach to optimize processes, systems, and organizations across various industries to improve efficiency and productivity.

3. What are some examples of successful applications of industrial engineering principles?

Examples include reducing production costs in manufacturing, improving patient flow in hospitals, optimizing transportation networks, and enhancing supply chain efficiency for businesses.

4. What skills are essential for success in industrial engineering?

Key skills for industrial engineers include analytical thinking, problem-solving, project management, communication, and proficiency in tools such as statistical software and simulation techniques.

5. How can individuals interested in industrial engineering stay updated on industry trends and advancements?

Joining professional organizations, attending conferences, participating in workshops, and pursuing continuing education opportunities are excellent ways to stay informed about the latest developments in industrial engineering.